Responding to the Need – PPE for the COVID-19 Pandemic

We can’t express enough gratitude to all of the healthcare professionals working so hard to care for us in a great time of need! As hospitals have struggled to get the protective equipment needed for their healthcare providers, we partnered with local companies Fabri-Kal, Schupan & Sons, and Southwest Michigan First to make face shields.

Bronson Healthcare requested support from Southwest Michigan First to acquire additional Personal Protection Equipment (PPE). With input from health care professionals, our companies were able to collaborate and adapt a concept design provided by Global Center for Medical Innovation (GCMI) consortium in less than one week.

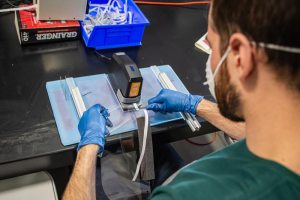

Each organization leveraged its specialty in the project. Fabri-Kal formed and cut the plastic shields then handed them off to Schupan & Sons to prepare the shields for assembly. We funneled all of the components of the project—foam, elastic and plastic shield—in order to assemble and then deliver to area hospitals.

Our manufacturing space and operations were at full capacity working on a different COVID-19 relief project so we set up the face shield line at our Innovation facility. Without assembly crew members, our designers and engineers stepped up and stepped into the role. Hear from Cassidy Taylor, a graphic designer who worked on the assembly line:

“One of the greatest things I’ve learned is how important it is to be flexible. With everything that has been happening in our world, country, and our own towns, society has made significant changes to our daily lives. It’s a scary time and an anxious time, but I’m also finding more and more moments of hope. One of those moments of great hope is Tekna’s ambition and ability to jump forward. In a matter of two weeks, we transformed our capabilities into one that is bringing hope and resources to not only people in our immediate community, but also to people far beyond our town.

I was asked to contribute to the production of the protective face shields that the hospital workers so desperately need. I spent the week rotating between stations on the production line with several other members of the company. From adhering the foam pad to the plastic shield, to bagging the completed product for shipping, we worked together to speed the production along. My coworkers and I come from desk jobs and we aren’t used to working on an assembly line. While the work is tedious and it’s not the normal graphic design work I’m used to, I actually found it to be pretty refreshing and it was nice to use a different side of my brain. The team and I also experienced a completely new type of collaboration. It encouraged all of us to remain flexible in our skills and minds, we communicated constantly, and worked together to achieve the goal of making as many masks as we could in each day. This experience was incredibly rewarding to be a part of! I’m so proud of the company, the team, and I’m thrilled to have the experience of bringing people hope and solace!” – Cassidy Taylor