Operation Birdhouse – Summer 2019

By Summer 2019 Interns: Eve Berndt, Lauren Maksymiuk, and Mike Stinchcomb

During the first few weeks of our internship, we heard talk of an intern project and a running joke about how the birdhouse is coming along. Around our last month at Tekna, we were given the project brief–operation birdhouse. The mission was to create a birdhouse for the back patio—but not just any old birdhouse. They wanted something exciting that pushed the stereotypical confines of everyday objects. We were given the choice to work individually or as a group, and we all decided we wanted to collaborate. Being the first group of interns to do this project, we wanted to set the bar high.

There were only a few parameters for the project: the birdhouse should represent the theme of transformation and we could only use materials found around Tekna. We had about a month until the final week of our internship to design, build, and brand our birdhouse. Below is a look at our thought process on each part of the project.

The Design – Eve Berndt

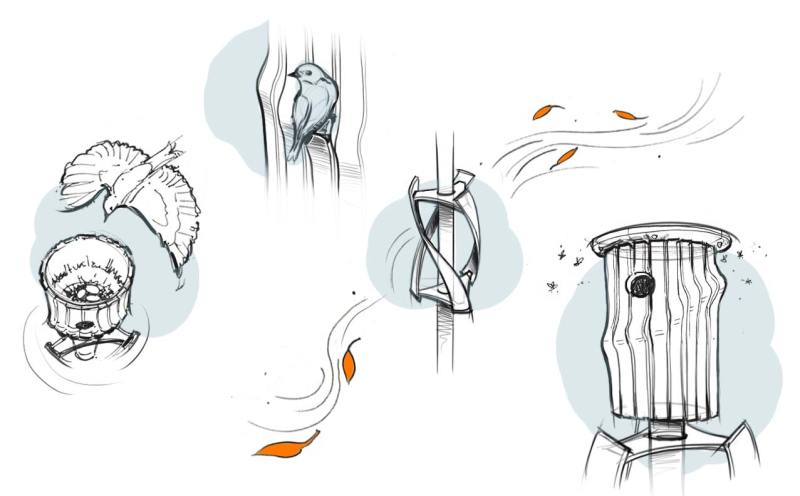

I always start with quick thumbnail sketches of how I want a product to function and in the first week of this process, our brainstorming sessions really fueled those sketches. We were interested in several ideas incorporating renewable energy and even waterfall features, but as we narrowed our concepts, we focused on what was feasible for us to build (and for Tekna to maintain). At one point, Mike suggested incorporating a wind-powered element, which we all thought was a cool feature and a viable energy source.

Once we chose the QR6 turbine, I started a lengthy process of shaping the birdhouse to pair well with the turbine. We had a very geometric design that we were interested in, but it didn’t have a single curve in it—there was nothing about it that was tying it to the organic, helical shape of the turbine. It’s important to stress these details, because even to non-designers when there’s something “off” about the proportions or curvature of a product, you can tell right away (though you might not be able to pinpoint what it is).

I began playing with tangencies between the profile of the house and the turbine blades, eventually incorporating a curvature pattern that moves in a wave across the panels that line the birdhouse. Each piece of wood has a single curve in it that gets lower and lower as you move from one panel to the next. When we decided on this direction, the curvature still looked a bit stagnant, so there was some work put into how each curve reflected light and how I could alter the location and prominence of the highlights and shadows. Because of the precise modifications, I was making, this was all done in CAD, which also made for a more accurate build later on.

It was exciting (and a bit stressful) to get into the woodshop and figure out the build process while navigating the materials available to us. We each had ideas to bring to the table, whether it was suggesting the best order of operations or where to put contrasting color. That was my favorite part of the process—crossing over disciplines and learning from one another. I think it made for a dynamic final product, one that we’re really proud to have contributed to.

The Engineering – Mike Stinchcomb

Upon being assigned this project, it became apparent that I would need to get creative with the design in order to challenge myself as an engineer. A birdhouse can have a creative form, but I wanted to add a creative function—something that’s not common among many birdhouses.

One idea I had was to use a DC motor to make a moving component. My first thought was to make a water pump with the motor and have a waterfall/birdbath on the birdhouse, but I quickly abandoned the idea because it would require far too much maintenance (replacing batteries, adding water, cleaning, etc.).

Then, I looked to something that would require less (or no) maintenance but still had a moving component. We landed on two ideas. One was to use a horizontal axis wind turbine to turn a camshaft, making the roof of the birdhouse oscillate and have a cool, wavy motion. The other was to make a fully sustainable birdhouse. This would require some form of renewable energy that could power lights, attracting bugs for the birds to feed on. We decided on this direction because it felt the most creative and thematic. Without the budget for the birdhouse, the renewable energy would have to be wind as there weren’t any solar panels lying around the building.

Through some research, I discovered that you can actually convert a DC motor into a generator. By spinning the top, it reverses the flow of current so that you can wire in something, like lights, to the other end and it will power them. The turbine would need to be a vertical axis wind turbine in order to tie in well with the overall design. We chose the QR6 design, which has a cool helical shape that we could tie the form of the birdhouse to and have the best performance for our application. It’s often used in urban environments due to its aerodynamic performance and its helical blade shape, which distributes loads evenly across each blade, reducing noise and vibration.

The next challenge was how to mount the turbine on the pole of the birdhouse without holding the turbine in compression and only using components around the building. It soon became apparent we would need to buy bearings to fit around the pole so the turbine would be able to spin freely. Our project leaders strongly supported mounting the turbine on the pole, so we were granted “buying power” to purchase these bearings.

We also ran into the challenge of turning the motor fast enough to power the lights. To troubleshoot this, we gear-drove the motor. This was easier to do with the turbine mounted on the pole because its rotational speed is greatly increased when transferred to the motor.

All in all, I’d say we were successful in adding a unique and creative function to the design and I found this challenge refreshing.

The Branding – Lauren Maksymiuk

Although I’ve had some experience with branding, I’ve never had to start all the way from the beginning–naming a product I helped create. At first, I didn’t know where to start. How do you come up with a creative name that flows and represents the product well? Fortunately, Tekna’s talented graphic design team had been through this process before and gave me tips on where to start. I began by writing themes that represented our birdhouse: sustainable, shelter, wind, movement, and more. Once I had some general ideas written down, the names started flowing. Some were better than others, but a few of the better names were BlueBreez, Gust Glow, and Lumina.

After coming up with some potential product names, I moved onto the logo design. This involved finding unique typefaces, sketching out simplified icons, and customizing letterforms. After several variations of each name, I narrowed it down to the three strongest options. Ultimately, BlueBreez was the chosen one. This logo represented several aspects of the birdhouse: the first part of the name, “blue,” was because the birdhouse was created specifically for Blue Birds; “breeze” represents the wind turbine that powers the lights on the birdhouse; the simplified wind icon connects to the name and has 3 parts to it, representing the three of us that worked on this project.

The finishing touch on the brand was creating the color palette. Due to the parameters of the project, we had limited colors of spray paint to choose from. Fortunately, there were shades of blue and orange that represented the bluebird and complemented each other well. We applied these colors to a model of the birdhouse before painting and found that the colors worked well when they were used subtly.

After creating a brand for our birdhouse, the finishing touch was a presentation about our process and a final poster. Creating the poster gave me ideas about how I could push the brand further and create a style guide for advertisements and other marketing materials. Even in a short span of time, being a part of this project gave me a sense of the full branding process and how a story unfolds as you create it.

Final Thoughts

As students who haven’t had exposure to working with people in multiple industries on one project, there was a lot of trial and error in the first few weeks. There were some design ideas that couldn’t be engineered, and there were some engineering functions that we had to design around. Building the birdhouse taught us how to manage our time, problem-solve, and take a project from start to finish. We’re excited to be the first of many Tekna birdhouses!