The Vacuum Cannon Chronicle

By Jonathan Penrod, Engineering Intern

When I applied for an engineering internship at Tekna, I had no idea what projects awaited me. Long calculations and paperwork were at the forefront of my imagination. But rather than a tedious stream of desk work, I’ve found myself engaged in interesting assignments every week—the most memorable involving a vacuum, PVC tubing, and a Ping-Pong ball.

One of my advisors had seen a video of engineers shooting a Ping-Pong ball through a Ping-Pong paddle and challenged me to reenact this during an “entertainment break” at a team luncheon.

A Method to Our Madness

First, I’ll tell you about the working concept behind our cannon design. The ends of a 1 ½” PVC pipe are sealed using tinfoil and duct tape after a Ping-Pong ball is placed inside. The PVC pipe has a pneumatic fitting in its wall allowing a vacuum pump to remove air molecules. This means that when either tinfoil cap is punctured, outside air rushes in, filling the vacuum space and forcing the Ping-Pong ball out the opposite end. The Ping-Pong ball accelerates as quickly as the air enters the chamber, as there’s hardly any air resistance on the vacuum side of the ball. This experiment can accelerate a Ping-Pong ball to over 400 mph!

To give the same ball more kinetic energy, we needed to accelerate it faster than the speed of sound. This poses a problem, as air does not naturally fill a vacuum any faster than the speed of sound due to micro eddies and swirls propagating the air. But the supersonic barrier can be broken if we use a converging/diverging nozzle. When a volume of gas (air in our case) moves through a narrowing tube, the particles accelerate due to the conservation of mass (the same volume of air that goes in one end has to come out the other). If the tube begins to diverge or get bigger, the air particles traveling subsonic begin to slow down.

Diverging Air(y) Quite Contrary

Something strange happens when air is traveling at the speed of sound: in the condensing nozzle (going from big to small), the air particles do not accelerate because they are already traveling at the speed of sound. If the same supersonic air passes through a diverging nozzle (going from small to big), the pressure of the gas decreases and the particles actually accelerate! Think of it as cars in a traffic jam on the freeway, when suddenly six lanes open up. The little air particles spread out and begin traveling faster. While this seems counter-intuitive, coupling a converging nozzle with a diverging nozzle actually accelerates air to the speed of sound on the converging side, but then it diverges and continues accelerating past supersonic speed—exactly the behavior we sought for our cannon!

Roll Out the Barrels

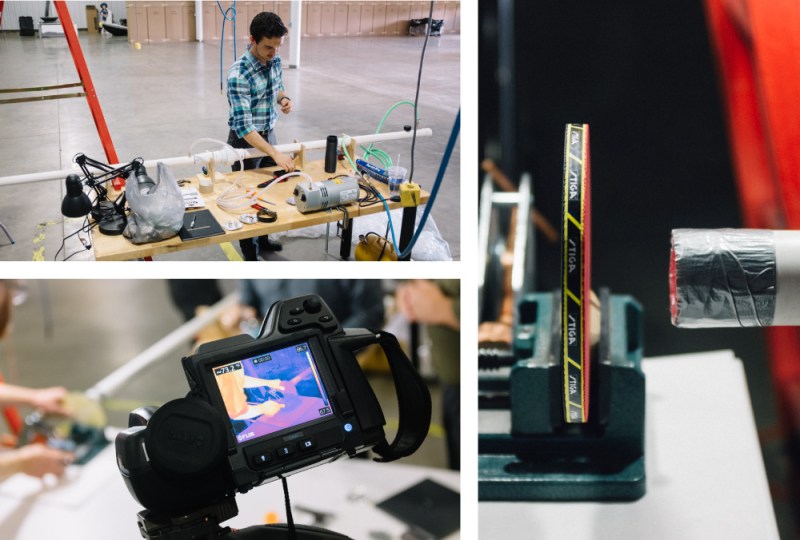

I designed a converging/diverging nozzle with SolidWorks and 3D printed a part overnight. I epoxied this nozzle into a section of PVC tubing and connected it to the end of our vacuum chamber. On the other side of the nozzle, I used a union to sandwich our tinfoil seal, which held back the pressure from a final pressure chamber. So now we have a vacuum tube for the Ping-Pong ball, a nozzle, and a pressure barrier made from aluminum foil that withholds the pressure from a final chamber. The idea is that I can pump up the pressure until it ruptures the middle aluminum barrier. The pressure difference will cause air to accelerate into the converging/diverging nozzle, which speeds the air past the sound barrier, potentially propelling the Ping-Pong ball out the barrel faster than the speed of sound.

Cannonball!

After assembling pneumatic fittings, pressure gages, PVC couplings, and hoses, I decided that the cannon was finally ready to go. I ran about 30 tests to figure out how many sheets of aluminum foil would be adequate for the vacuum chamber end caps—settling on three for the barrel end and 10 between the pressure chamber and the nozzle. We set up a few cameras and even included a thermal imaging unit to capture the cannon in all its glory! Filling the pressure chamber for the final run was verysatisfying. The pressure climbed to just over 80psi before rupturing the aluminum seal with a loud crack. Different runs sent the Ping-Pong ball through a pizza box, into a block of structure foam, and cracked the handle of a Ping-Pong paddle. While our process didn’t quite achieve the same clean hole that we saw in the initial video, we decided that we could improve our design in the future.

Team Tekna for the Win

Reflecting on our cannon vacuum experiment, I’m amazed at how unique and fun the experience has been—where else but Tekna would I be able to build cannons for lunch entertainment? Ultimately, aside from the good times, I also gained some very valuable lessons. The project pushed me creatively, mathematically and also helped me understand how to pace my research while adhering to deadlines and a budget —all while working in a team environment. I am so grateful for the resourcefulness and fun that Tekna encourages every day, and I can’t wait for the next chapter!