Fenwick Fishing

Industrial Design / Human Factors / CMF / CAD

Fenwick joined forces with us to redesign their offerings and bring ergonomic expertise to their full line of spinning and casting rods.

Guided by Fenwick’s belief that the hands are the best piece of fishing gear and the mantra “Feel Everything”, we combined our expertise in design process and ergonomics with Fenwick’s vast fishing knowledge to create a distinctive lineup of fishing rods that blends tradition with cutting edge rod technology.

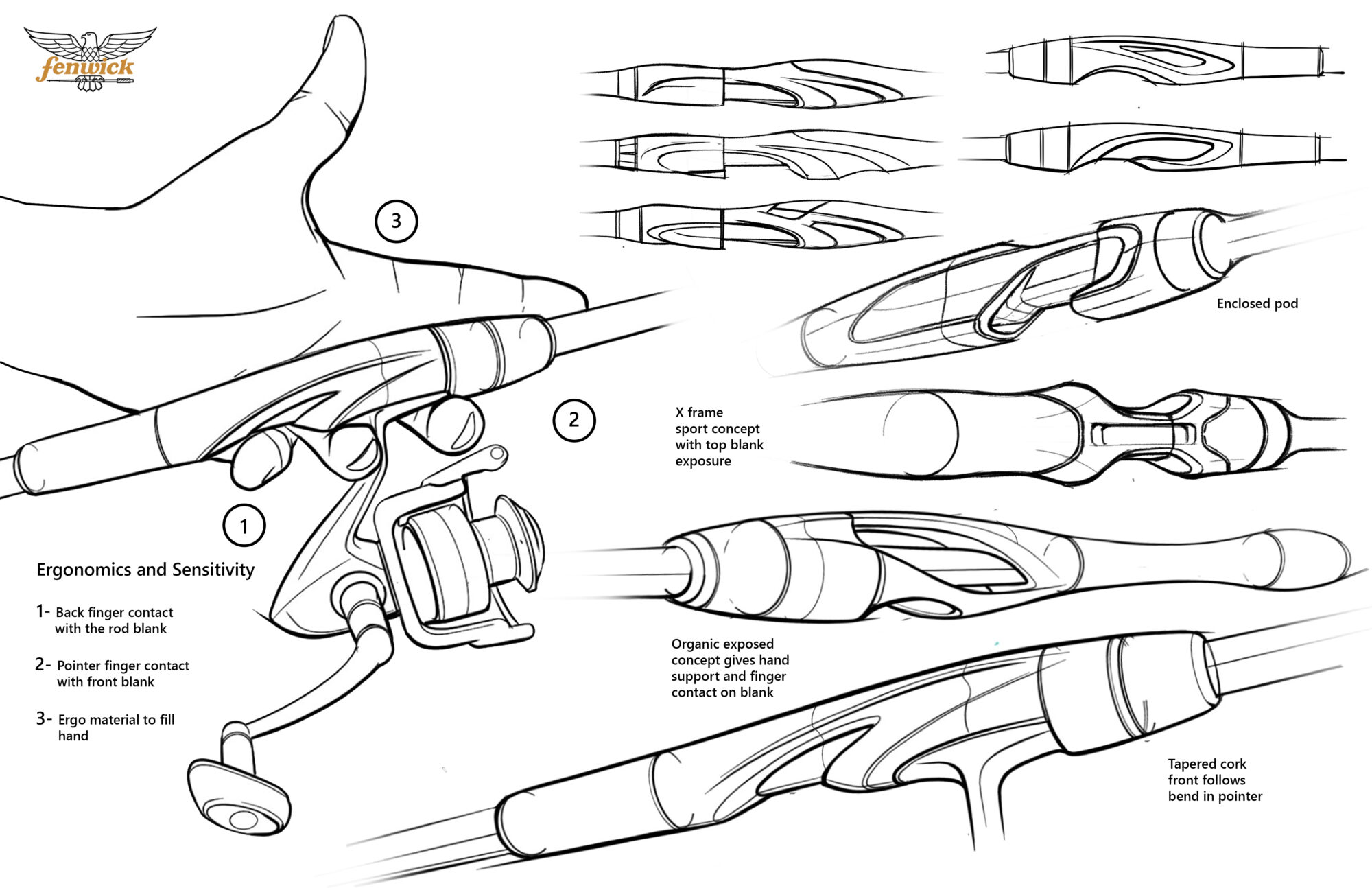

The goal was twofold: to create a seamless connection between the user and the rod through improved hand position and ergonomics and to solidify Fenwick’s position as a premium rod brand in the market. Our strength in human factors, developed over decades of designing surgical instruments, was a natural fit for the sensitive and precise nature of these handheld products.

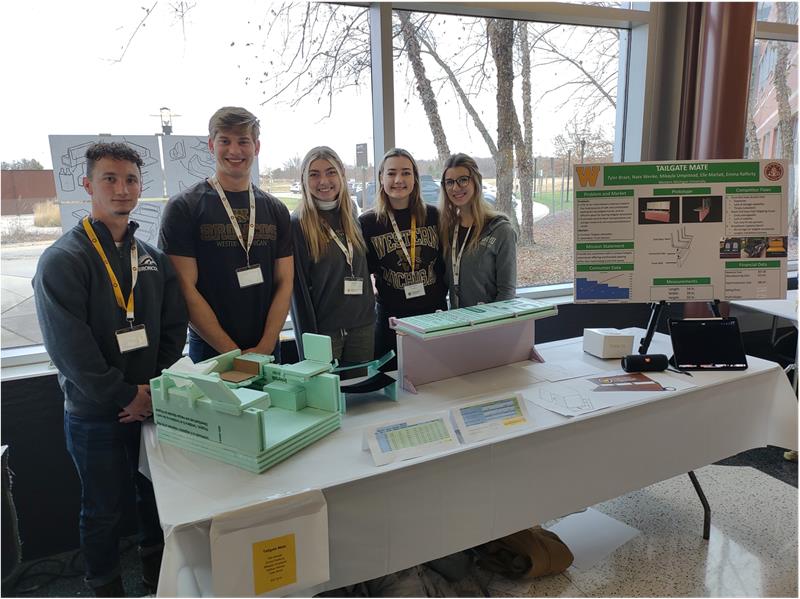

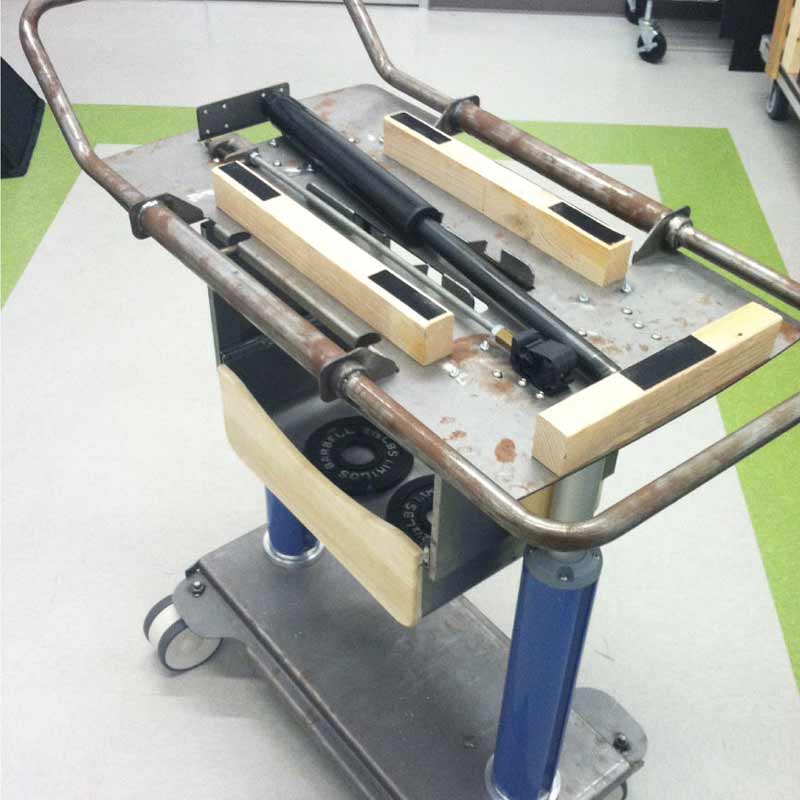

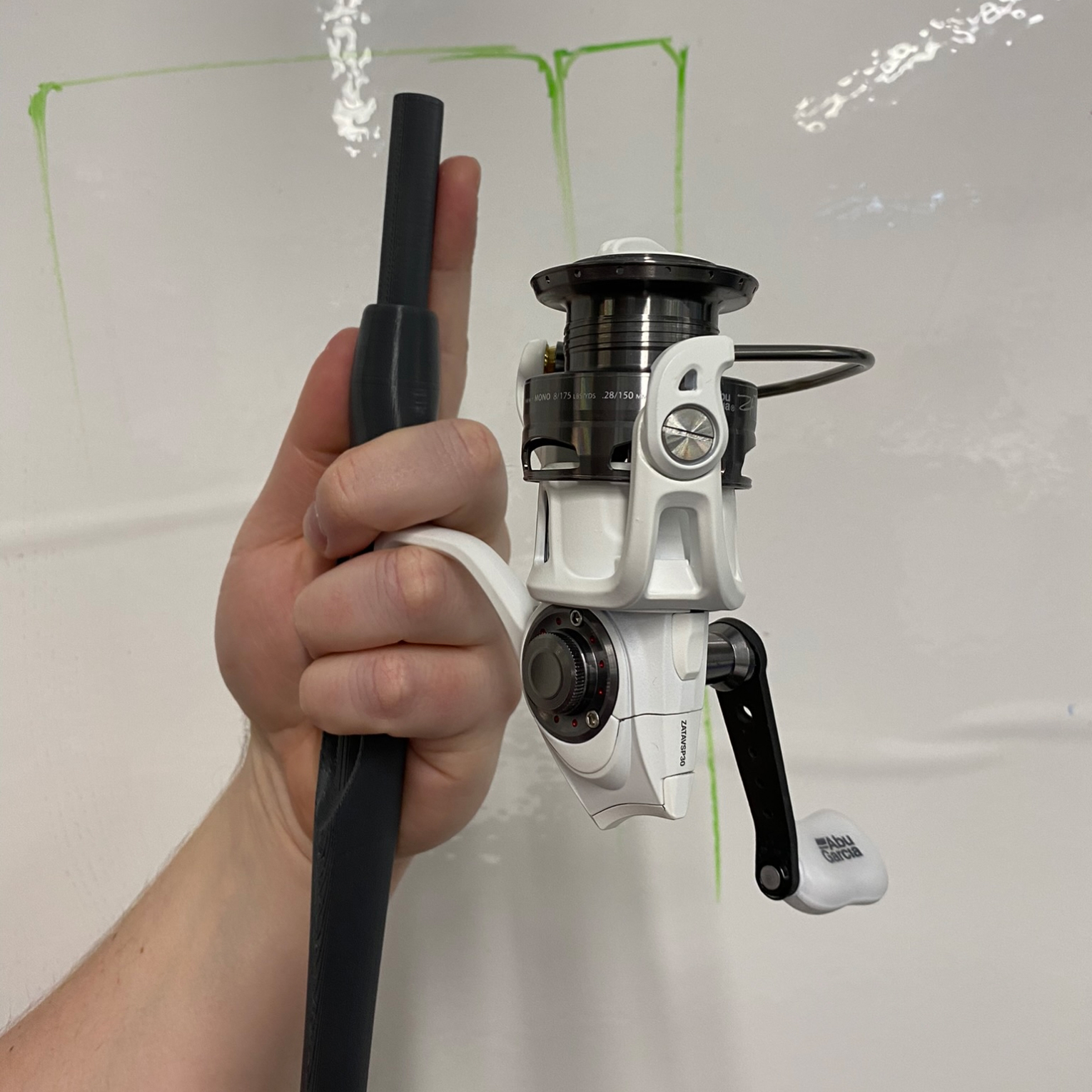

Benchmarking a variety of rods on the market and understanding the nuanced ergonomic needs of fishing rod design was a crucial early step in the process. Tekna’s experience with precision tools to complete delicate work combined with Fenwick’s vast knowledge was a great collaboration.

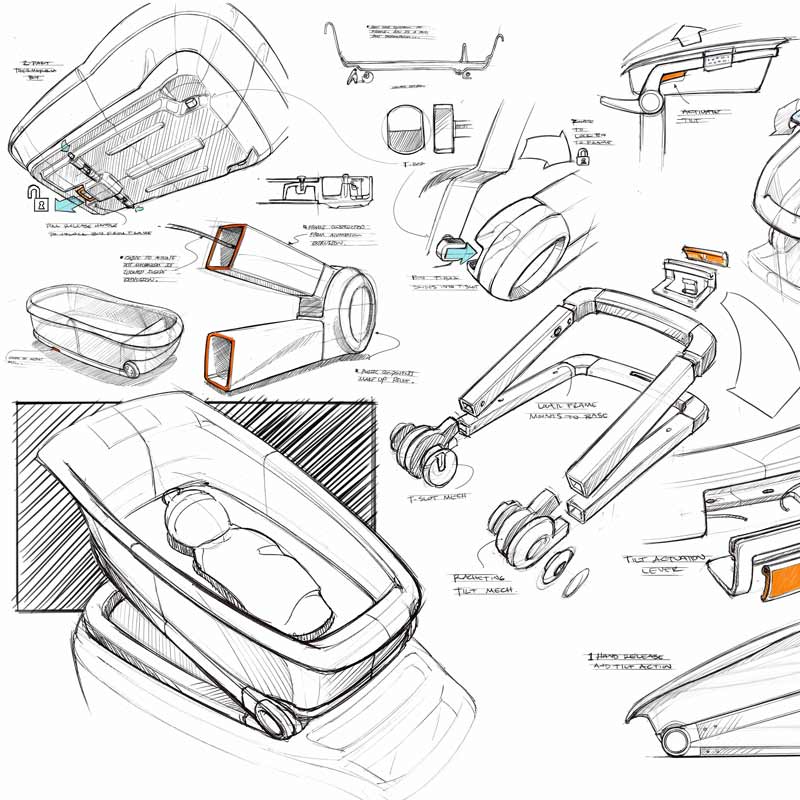

The Tekna Design and Research team collected insights from a variety of industries and analogous products including watches, bicycles, hunting bows, and ski equipment. We channeled this inspiration from multiple inputs, ultimately designing a rod that resonates with those who appreciate finely crafted objects and embrace the outdoors.

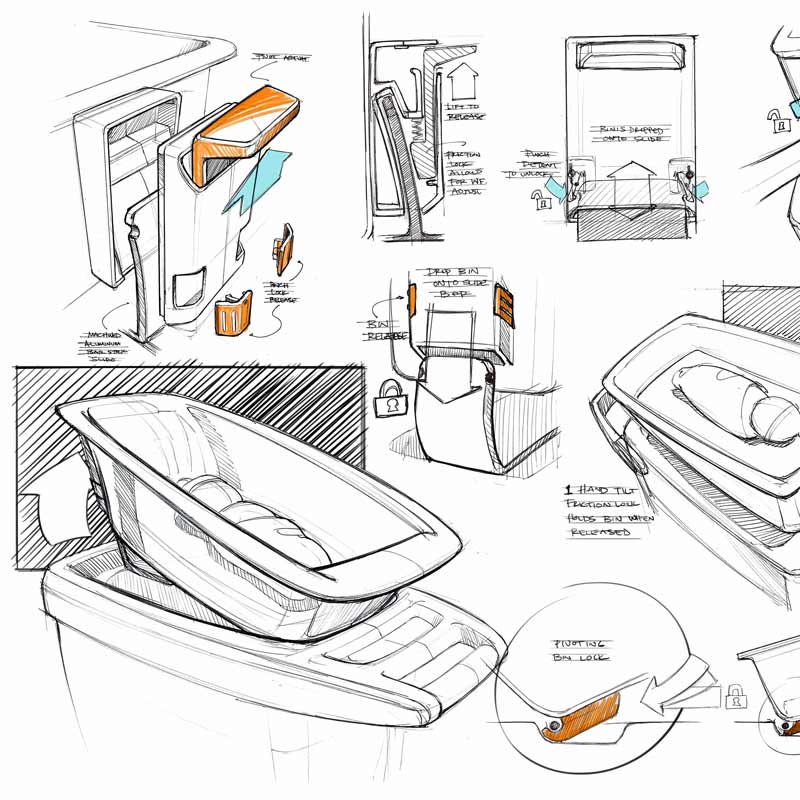

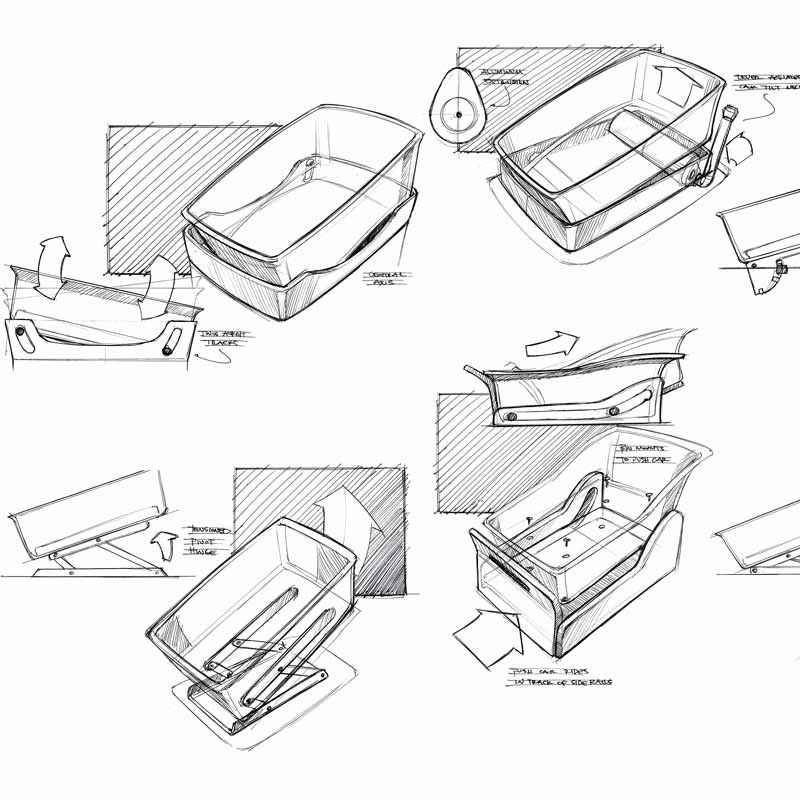

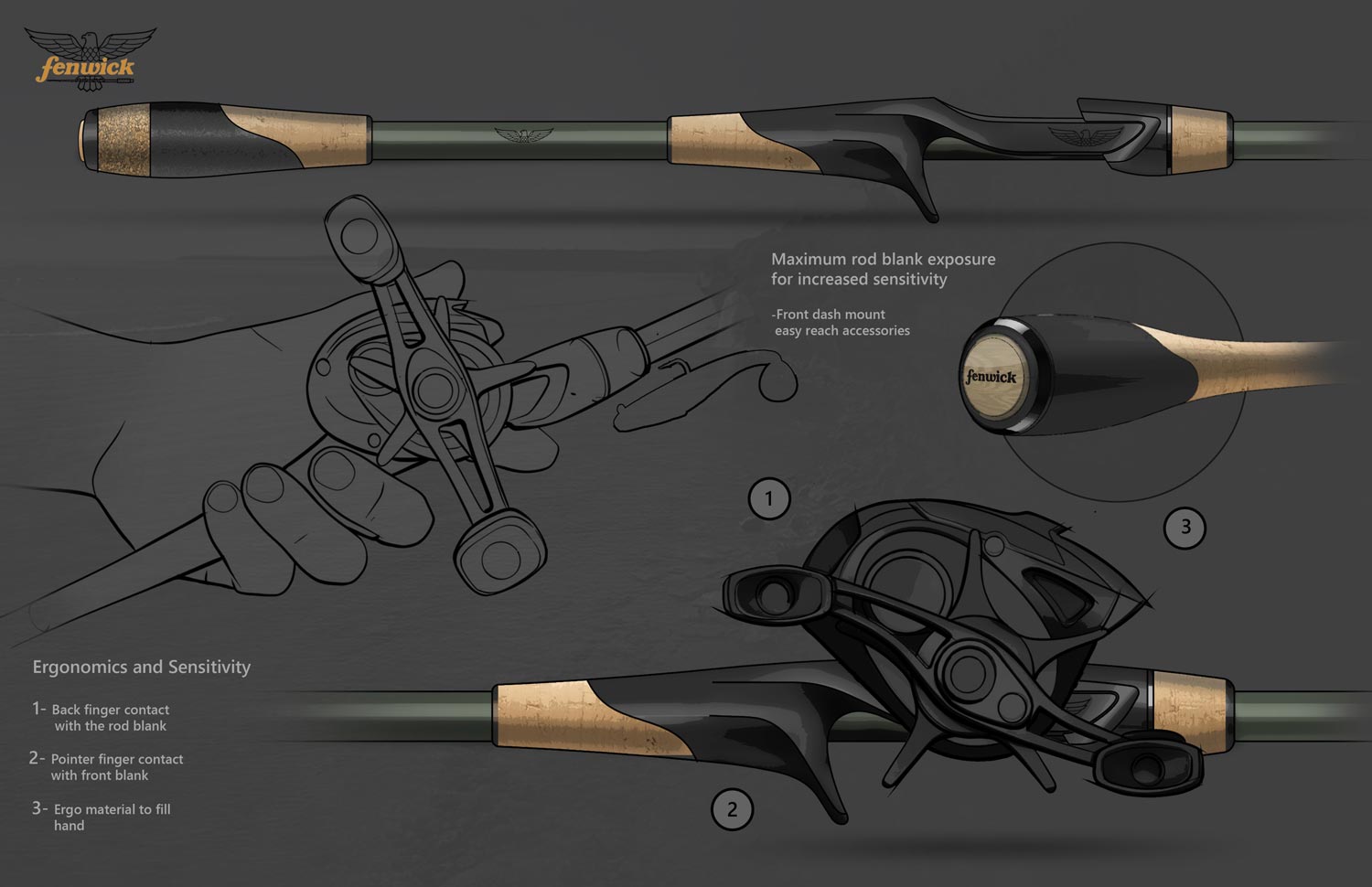

Armed with a deep understanding of the end user and the nuances of the sport, we combined aesthetic themes that aligned with the Fenwick Brand with our learnings from user research to develop a variety of concepts.

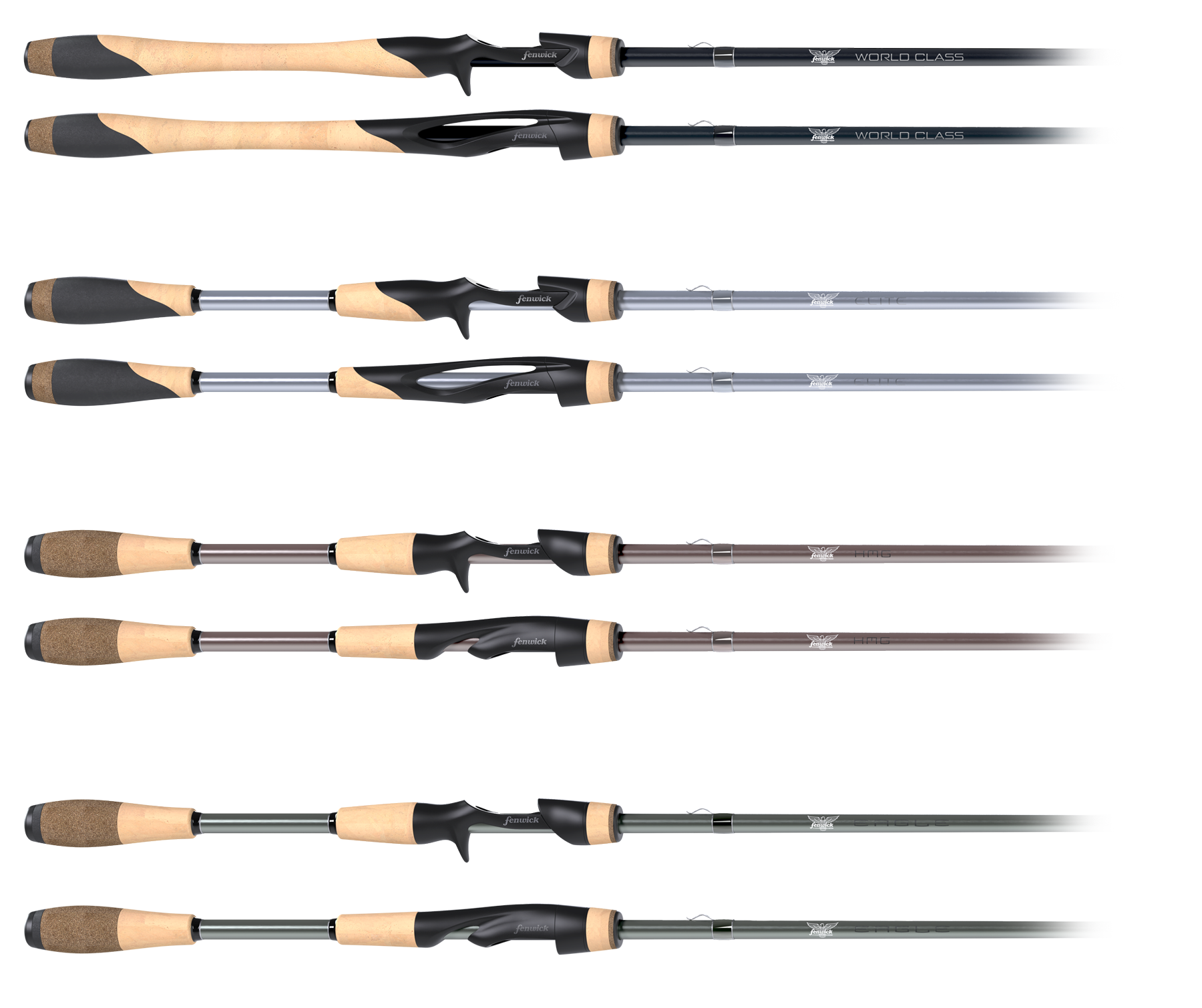

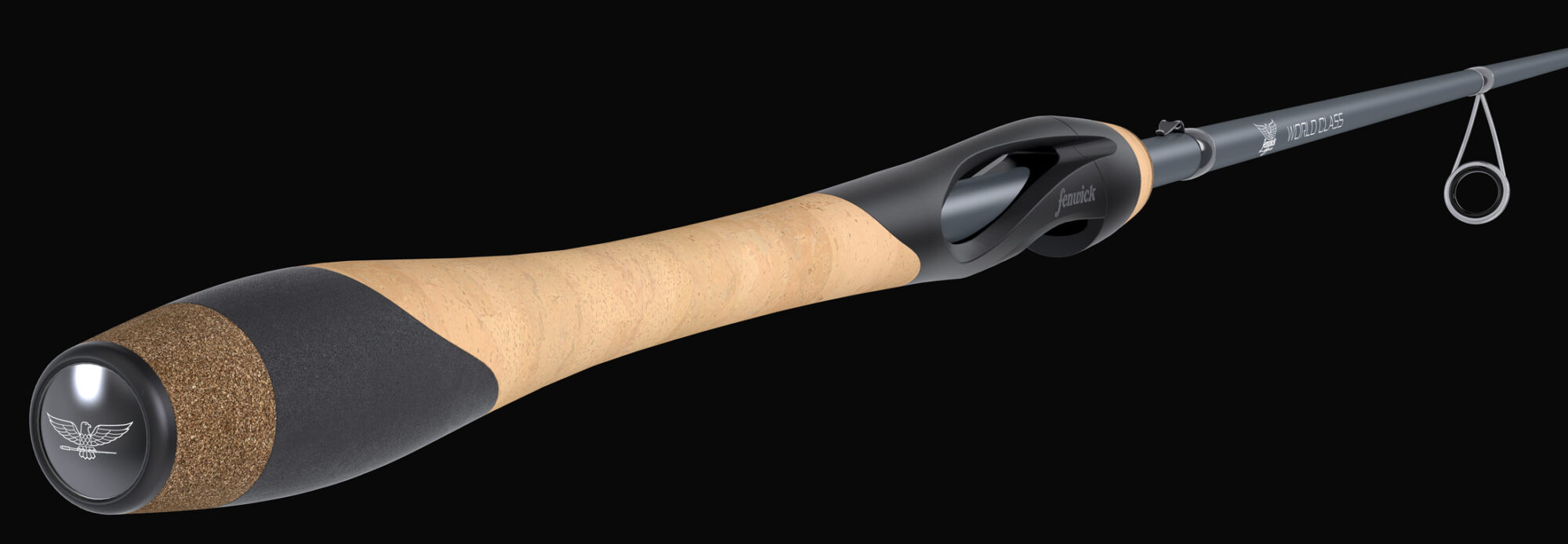

The Design team selected colors, material and finishes to distinguish between four different series in the Fenwick portfolio. Subtle tones combined with natural cork reinforce Fenwick’s brand. Careful application of trim, logos, and graphics completes the aesthetic.

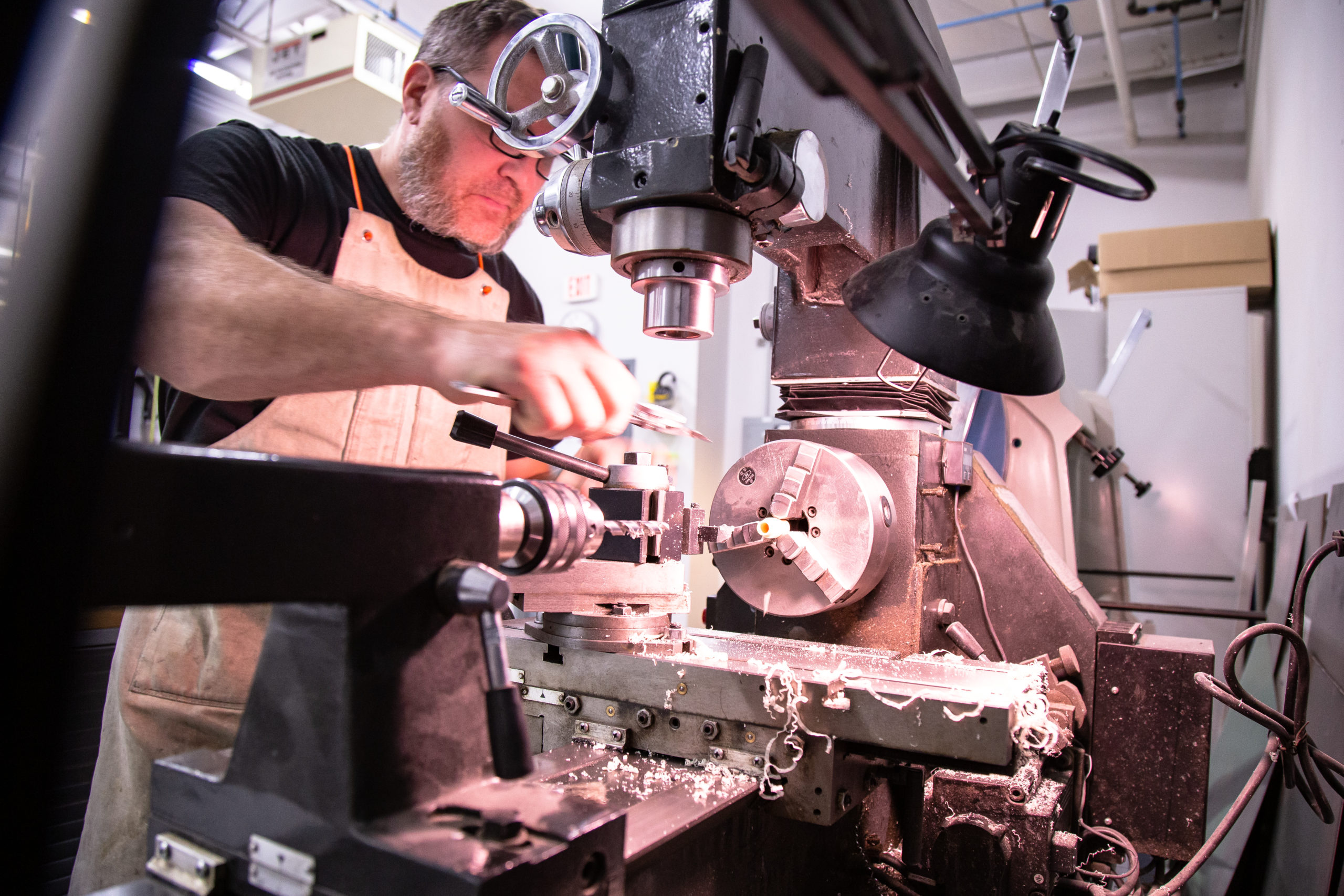

To ensure the best possible hand feel, we developed and produced 3D printed rapid prototypes and completed end user testing to gain confidence to fine-tune the final design direction.

The final parametric Solidworks CAD models were created for each rod in each series and delivered with high resolution renderings and product style guidelines.

Our collaborative effort resulted in the design of a comprehensive rod lineup covering over 200 SKUs across four series. The solution focuses on creating a clear distinction between the four Fenwick series, emphasizing performance, human factors, brand, and aesthetics.

Using a proven human-centered design process, the collaboration between Tekna and Fenwick resulted in a successful new product launch. The new grip design not only improves the ergonomics and hand feel of the rods but also reinforces Fenwick’s position as a premium brand with a strong presence in the fishing market.